Muffle Furnace

Muffle Furnace Specification

- Accuracy

- 2C

- Technology

- Electric Heating

- Operating Pressure

- Atmospheric

- Automation Grade

- Semi Automatic

- Power Source

- Electric

- Accessories Type

- Crucible, Tongs, Tray

- Surface Treatment

- Powder Coated

- Machine Type

- Bench Top

- Control System

- Digital Temperature Controller

- Features

- High Thermal Efficiency, Fast Heating, Energy Saving

- Material

- Mild Steel Body with Ceramic Insulation

- Function

- High Temperature Heat Treatment

- Application

- Laboratory, Research, Industrial Applications

Muffle Furnace Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 04 Per Month

- Delivery Time

- 3-8 Week

About Muffle Furnace

With our modernized and core infrastructure facility, we are committed to manufacture and supply a remarkable range of Muffle Furnace. These furnaces are used in various sectors including metal treatment, ash determination, medical, agricultural, industrial and research laboratories. Light weight, fast heating and easy operation are some of the salient attributes of our Muffle Furnace. In addition, our furnaces are manufactured using power coated MS and insulating materials at our state of the art machining facility.

Specifications:

-

Max. Temp. 1000Deg.C/1200Deg. C & working temp. 930Deg.C/1130Deg.C

-

Temp. controlled by Digital Temp. Controller cum Indicator.

-

Heating Element made of Kenthal Wire

-

A uniform heat distribution through all 4 sides with Kenthal wire.

-

A special solid state silver fuse for protection to elements in case of over heating

-

Operates on 230 Volts, AC only

Standard Sizes

-

9" x 4" x 4"

-

10" x 5" x 5"

-

12" x 6" x 6"

-

18" x 9" x 9"

Advanced Heating Technology

Utilizing Kanthal A1 or Nichrome wire, the furnace achieves fast, efficient heating up to 1200C. Its ceramic fiber wool insulation enables high thermal efficiency, safeguarding samples and operators during high-temperature heat treatments.

Precision Control and Safety

Equipped with a digital temperature controller and LED display, users can precisely manage conditions with accuracy of 2C. The ceramic-lined, front-opening door enables secure sample handling and minimizes heat loss during operation.

Versatile Laboratory and Industrial Applications

Designed for laboratories, research facilities, and industry, the furnace caters to high-temperature processing such as material testing, ashing, and sintering. Semi-automatic operation and essential accessories streamline workflow and enhance usability.

FAQs of Muffle Furnace:

Q: How does the muffle furnace ensure temperature uniformity within the chamber?

A: The furnace maintains temperature uniformity better than 10C throughout the chamber, thanks to its efficient heating elements and high-quality ceramic fiber insulation, promoting consistent and reliable heating for samples.Q: What is the maximum temperature the muffle furnace can reach, and what types of heat treatment processes is it suitable for?

A: The furnace reaches up to 1200C, making it ideal for various high-temperature heat treatment processes, including ashing, sintering, annealing, and material characterization in laboratory and industrial settings.Q: When should the accessories like crucible, tongs, and tray be used during furnace operation?

A: Accessories such as crucible, tongs, and tray should be used when loading or unloading samples to ensure safe handling and to protect both users and inner furnace surfaces from thermal exposure and contamination.Q: Where is this muffle furnace commonly utilized?

A: This bench-top muffle furnace is widely employed in laboratories, research institutions, and various industrial applications, primarily for precision heat treatments and material testing at atmospheric pressure.Q: What benefits does the ceramic fiber wool insulation offer in this furnace?

A: Ceramic fiber wool insulation provides high thermal efficiency, rapid heating, reduced energy consumption, and enhanced safety by minimizing surface temperature and preventing heat loss during operation.Q: How does the LED digital display and digital temperature controller improve user experience?

A: The LED digital display coupled with a digital temperature controller allows for accurate, easy-to-read temperature monitoring and adjustment, ensuring precise control over heat treatment parameters and improved process reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metallurgical Engineering Lab Instruments Category

Riffle Sample Divider

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Automation Grade : Manual

Technology : Manual Sampling

Material : Mild Steel / Stainless Steel

Surface Treatment : Polished & Painted

Roll Crusher

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Automation Grade : SemiAutomatic

Technology : Double Roll Crushing

Material : Mild Steel

Surface Treatment : Paint Coated

Computerized Universal Testing Machine

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Automation Grade : Automatic

Technology : Computerized

Material : Mild Steel

Surface Treatment : Powder Coated

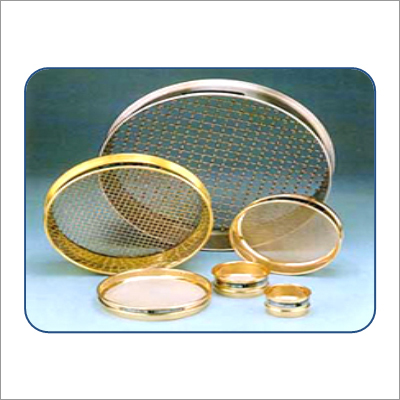

Test Sieves

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Automation Grade : Manual

Technology : Perforation & Weaving

Material : Stainless Steel 304

Surface Treatment : Polished Stainless Steel

Factory Address :

Plot No 47, Emerald Indl Estate, Kidc Indl Area, Deku Village, Khalapur Taluk,

Khopoli Raigad, Maharahtra

Send Inquiry

Send Inquiry