Roll Crusher

Roll Crusher Specification

- Machine Type

- Heavy Duty Crusher

- Power Source

- Electric

- Operating Pressure

- Standard Atmospheric Pressure

- Control System

- Manual/PLC based

- Accessories Type

- Wear Resistant Rollers

- Technology

- Double Roll Crushing

- Automation Grade

- Semi-Automatic

- Accuracy

- High Precision

- Surface Treatment

- Paint Coated

- Features

- High throughput, Low maintenance, Uniform particle size, Robust construction

- Type

- Roll Crusher

- Material

- Mild Steel

- Function

- Crushing of materials such as rocks, ore, coal

- Application

- Mining, Cement, Aggregate, and Power plants

- Voltage

- 220-440V

- Drive Type

- Gear/Chain Coupled

- Discharge Size

- Adjustable 1 mm - 10 mm

- Feed Size

- Up to 30 mm

- Noise Level

- Low

- Roller Diameter

- 300 mm to 600 mm

- Weight

- 1500 kg (approx)

- Safety

- Overload protection

- Capacity

- Up to 100 TPH

- Roller Material

- Alloy Steel with surface hardening

Roll Crusher Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 04 Per Month

- Delivery Time

- 3-8 Week

About Roll Crusher

Our painstaking efforts towards client satisfaction have led us in manufacturing and exporting an innovative range of Roll Crusher. These crushers are capable of crushing hard materials and brittle with very low fines generation. Our Roll Crusher is made by a team of skilled professionals by using quality tested materials, following the norms and guidelines laid down by the industry. Rugged construction, negligible maintenance and advanced operation life are some of the salient attributes of our crushers.

Specifications:Very hard rolls of alloy steel crushers are also available with the same roll sizes Separate drive for each roll is given ao that rolls break the particles with minimum friction. No RCC foundation is required if fixed on a specially designed AVM pad frame.

| Model | Roll Dia. | Width mm | Two Motors Each HP | App. Production |

|---|---|---|---|---|

| PRC-3012 | 300 | 120 | 3 & 5 | 2 TPH |

| PRC-4020 | 400 | 200 | 5 & 7.5 | 5 TPH |

| PRC-4040 | 400 | 400 | 7.5 & 10 | 8 TPH |

| PRC-6040 | 600 | 400 | 10 & 15 | 12 TPH |

| PRC-6060 | 600 | 600 | 15 & 25 | 18 TPH |

| PRC-8040 | 800 | 400 | 15 & 25 | 18 TPH |

| PRC-8060 | 800 | 600 | 25 & 40 | 25 TPH |

| PRC-8080 | 800 | 800 | 40 & 50 | 35 TPH |

| PRC-80100 | 800 | 1000 | 40 & 60 | 45 TPH |

Superior Double Roll Crushing Technology

Harnessing advanced double roll crushing, this machine delivers efficient and uniform material reduction with minimal fines. Alloy steel rollers with surface hardening ensure extended durability, making it suitable for constant operation in harsh industrial environments. Benefit from a combination of rugged construction, precise sizing, and effortless maintenance.

Versatile Applications in Industry

The Roll Crusher is ideal for reducing various materials such as rocks, ores, and coal, serving sectors like mining, cement, aggregates, and power generation. Its adaptable discharge size and consistent output make it particularly valuable for processing bulk materials that require controlled, uniform particle sizing.

Safety and Operational Efficiency

Engineered with built-in overload protection and constructed for low noise, this crusher prioritizes safety and operator comfort. Its semi-automatic operation, high accuracy, and manual or PLC-based control systems provide flexible, user-friendly performance while minimizing downtime and maximizing productivity.

FAQs of Roll Crusher:

Q: How does the Roll Crusher ensure uniform particle size during operation?

A: The Roll Crusher uses double roll crushing technology with precisely engineered alloy steel rollers. The discharge size can be easily adjusted between 1 mm and 10 mm, allowing consistent, high-precision output suitable for various applications.Q: What materials can be processed using this Roll Crusher?

A: This heavy-duty crusher is designed to handle rocks, ores, coal, and similar materials. It is commonly used in mining, cement manufacturing, aggregate production, and power plants.Q: When should I consider using a Roll Crusher in my process line?

A: Roll Crushers are ideal when you need controlled particle reduction, high throughput (up to 100 TPH), and uniform sizing. Theyre suitable for both primary and secondary crushing tasks that demand low maintenance and precise output.Q: Where can the Roll Crusher be installed for optimal performance?

A: The Roll Crusher can be integrated into mining, cement, aggregate, or power plant facilities. It should be installed on a stable foundation and operated under standard atmospheric pressure with access to a 220440V electric power source.Q: What makes the Roll Crusher a low-maintenance solution?

A: It features wear-resistant, surface-hardened alloy steel rollers and a robust mild steel frame. The gear/chain coupled drive system is engineered for smooth, quiet operation and longevity, reducing maintenance requirements.Q: How does the overload protection system work in this Roll Crusher?

A: The built-in overload protection mechanism automatically prevents roller or drive damage by disengaging the drive or halting operation during excessive load conditions, safeguarding both the machine and operator.Q: What are the main benefits of using this Roll Crusher?

A: Key benefits include high throughput, uniform product size, low operating noise, robust construction, overload protection, and ease of adjustment, making it a reliable and versatile option for industrial crushing applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metallurgical Engineering Lab Instruments Category

Riffle Sample Divider

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Material : Mild Steel / Stainless Steel

Accuracy : High sample division accuracy, typically 2%

Surface Treatment : Polished & Painted

Application : Soil, cement, aggregates, and other powder/granular sample splitting

Hot Air Laboratory Oven

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Material : Mild Steel (MS) / Stainless Steel (SS)

Accuracy : 1C

Surface Treatment : Powder Coated

Application : Laboratories, Research Centers, Industrial Testing

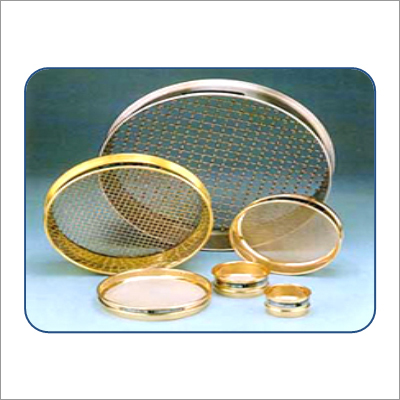

Test Sieves

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Material : Stainless Steel 304

Accuracy : Precision manufactured to ASTM & ISO standards

Surface Treatment : Polished Stainless Steel

Application : Soil, Aggregate, Chemical, Pharmaceutical Sampling

Blaine's Apparatus-Average Particle Size Analyser

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Material : Borosilicate Glass & Metal Stand

Accuracy : 1% (based on proper usage)

Surface Treatment : Polished

Application : Used in laboratories for testing cement and other fine powders

Factory Address :

Plot No 47, Emerald Indl Estate, Kidc Indl Area, Deku Village, Khalapur Taluk,

Khopoli Raigad, Maharahtra

Send Inquiry

Send Inquiry