Riffle Sample Divider

Riffle Sample Divider Specification

- Machine Type

- Laboratory Equipment

- Technology

- Manual Sampling

- Operating Pressure

- Ambient

- Accessories Type

- Sample pans, collection containers

- Control System

- Manual Handles

- Power Source

- Manual

- Accuracy

- High sample division accuracy, typically 2%

- Features

- Corrosion resistant; Portable; Easy to clean and maintain; Supplied with interchangeable riffle boxes

- Surface Treatment

- Polished & Painted

- Automation Grade

- Manual

- Type

- Sample Divider

- Material

- Mild Steel / Stainless Steel

- Function

- Evenly splits and divides powder, granular, and bulk materials for sampling

- Application

- Soil, cement, aggregates, and other powder/granular sample splitting

- Voltage

- Not required (manual operation)

Riffle Sample Divider Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 04 Per Month

- Delivery Time

- 3-8 Week

About Riffle Sample Divider

Being committed towards ensuring complete client satisfaction, we are manufacturing and exporting an exceptional range of Riffle Sample Divider. Made and designed using premium quality materials and modern technologies, these dividers are used for sampling aggregates ores refractory materials, pigment soap, cement and powdered coal. Owing to characteristics like negligible maintenance, easy operation and modular design, our Riffle Sample Divider is cherished and appreciated over the global platform.In addition, we are capable of customizing these dividers as per the needs of the clients.

Specifications:

It consists of a sheet metal box mounted on legs and fitted with a series of chutes or equal width which discharge the material alternatively in opposite directions into speculate panes. The chutes of the riffle are steep enough to allow rapid flowing of the material .

| Chute Width | No of Chutes |

|---|---|

| 12.5mm | 16 |

| 20mm | 16 |

| 25mm | 12 |

| 38mm | 12 |

| 50mm | 8 |

Precision Sampling for Laboratories

Engineered for reliable and repeatable division of powder, granular, and aggregate samples, the Riffle Sample Divider is widely used in laboratory testing and quality control. Its robust construction and adjustable slots ensure consistency and accuracy, making it suitable for regulatory and industrial applications where representative sampling is critical.

Versatility Across Multiple Materials

Suitable for soil, cement, and aggregates, this sample divider supports a wide range of laboratory applications. Available in different configurations, it seamlessly handles sample materials with varying particle sizes. Its interchangeable riffle boxes and choice of finishes (smooth powder coated or mirror finish SS) cater to specific laboratory needs.

Manual Operation for Greater Control

Equipped with manual handles and requiring no electrical supply, the Riffle Sample Divider offers dependable sampling without the constraints of automation. Its simple yet effective control system provides operators full oversight during sample division, ensuring high accuracy and minimal contamination risk.

FAQs of Riffle Sample Divider:

Q: How does the Riffle Sample Divider ensure accurate sample splitting?

A: The Riffle Sample Divider uses a series of precision-cut slots (fixed or adjustable between 10 mm and 25 mm) to evenly distribute bulk material into multiple collection pans. This mechanism ensures a representative and unbiased sampling, with typical division accuracy within 2%, ideal for laboratory and quality control applications.Q: What types of materials can be processed using this sample divider?

A: This equipment is suitable for splitting a wide range of powder, granular, and bulk materialscommonly soil, aggregates, cement, and various laboratory test samples. Its adjustable slots and durable construction make it versatile for different sample types in laboratory environments.Q: When should a laboratory use a riffle sample divider?

A: A riffle sample divider should be used whenever precise and representative sample subdivision is required prior to analysis. It is particularly necessary in routine soil, cement, and aggregate testing to ensure that all portions of the sample accurately reflect the whole.Q: Where are riffle sample dividers typically used?

A: These dividers are predominantly used in materials testing laboratories, research facilities, and quality control departments involved with construction materials, soil science, or industrial powders, including cement manufacturing and mineral analysis.Q: What is the proper process for using the Riffle Sample Divider?

A: To use, load the sample into the top of the divider. Operate the manual handle if present, allowing the material to pass through the riffle slots. Collect the subdivided samples in the supplied pans below, alternating between them for true representativity. The device is portable and easy to clean after each use.Q: What benefits does this sample divider offer compared to manual hand splitting?

A: The riffle sample divider minimizes the risk of bias and human error inherent in manual splitting. It enables quick, standardized, and accurate sample division, improves repeatability of results, and ensures compliance with international standards such as IS 1607 and ASTM C136.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metallurgical Engineering Lab Instruments Category

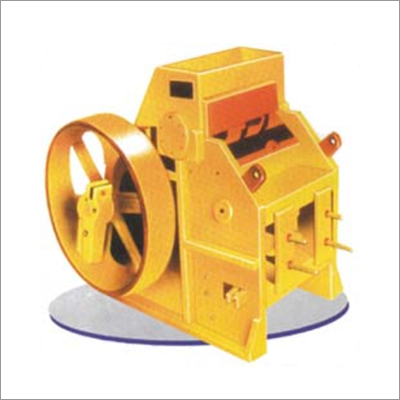

Jaw Crusher

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Technology : Mechanical crushing

Machine Type : Heavy Duty Crusher

Surface Treatment : Paint Coated

Material : Cast Iron & Mild Steel

Muffle Furnace

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Technology : Electric Heating

Machine Type : Bench Top

Surface Treatment : Powder Coated

Material : Mild Steel Body with Ceramic Insulation

Computerized Universal Testing Machine

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Technology : Computerized

Machine Type : Servo Controlled

Surface Treatment : Powder Coated

Material : Mild Steel

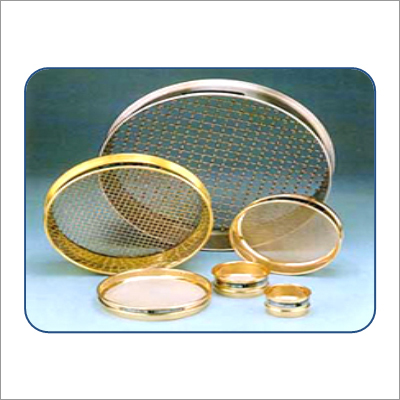

Test Sieves

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Technology : Perforation & Weaving

Machine Type : Manual Sieve

Surface Treatment : Polished Stainless Steel

Material : Stainless Steel 304

Factory Address :

Plot No 47, Emerald Indl Estate, Kidc Indl Area, Deku Village, Khalapur Taluk,

Khopoli Raigad, Maharahtra

Send Inquiry

Send Inquiry