Computerized Universal Testing Machine

Computerized Universal Testing Machine Specification

- Technology

- Computerized

- Accessories Type

- Grips, Extensometer, Compression Platens, Bending Attachments

- Operating Pressure

- Hydraulic, Up to 200 bar

- Automation Grade

- Automatic

- Surface Treatment

- Powder Coated

- Accuracy

- 1% of indicated load

- Power Source

- Electric

- Machine Type

- Servo Controlled

- Control System

- Microprocessor/PC Based

- Type

- Universal Testing Machine

- Material

- Mild Steel

- Function

- Tensile, Compression, Bending and Shear Testing

- Application

- Material Strength Testing in Laboratories and Industries

Computerized Universal Testing Machine Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 04 Per Month

- Delivery Time

- 3-8 Week

About Computerized Universal Testing Machine

We have attained the market credibility by manufacturing and exporting a remarkable range of Computerized Universal Testing Machine. Enabled with windows operating system, these machines are used for a variety of tests like tension, compression, transverse, bend, shear and brine hardness of metals. Our Computerized Universal Testing Machine is made by a team of skilled professionals, following the norms and guidelines laid down by the industry. We lay prime emphasis on the packaging of these machines for safe delivery at clients premise.

Specifications:

- Computer Controlled Mechanism under Windows 2000/XP

- Variable Speed Drive with AC Servo Drive

- Automatic Identification and Interchangeability of Load Cells

- Different clamping devices to suit specific test equipment

- Safety interlock by end limit switches and by overload sensing

| Max. Test Load | 5KN, (as desired for Iron Pellets) 10Kn is also available |

|---|---|

| Load Measurement | Exchangeable Strain Gauge based Load Cell |

| Load Measuring Accuracy | +/- 1% on indicated load from 2% - 100% of load capacity |

| Max Cross Head Stroke | 1000mm without Load Cell & Grips |

| Distance between columns | 350mm |

| Drive System Details | Ball Screws with AC Servo Motor of Mitsubishi with digital drive speed from 0.5mm-500mm per minute Stepless |

| Application software for Iron Pellet Testing | Special software Window XP Based |

| Cross head Display Resolution | 0.01mm by means of Rotary Ecoder |

| Power Supply | 230VAC/ 50Hz Single Phase |

| Load Range & Resolution | 1/10000 from 0.40% of range and 1/4000 from 40-100% of range. |

Robust Construction with Customizable Capacity

Constructed from powder-coated mild steel, this testing machine features a durable twin-column frame, capable of withstanding intensive testing processes. The load capacity is customizable, ranging from 10kN to 2000kN, making it suitable for a wide array of material testing applications across multiple industries.

Advanced Technology and Versatile Connectivity

Equipped with a strain gauge-based load cell and a digital LCD/PC interface, the machine ensures high-precision testing and data acquisition. It offers comprehensive connectivity through USB, RS232, and LAN options, allowing users to integrate their results into laboratory and industrial data systems seamlessly.

Automated, Safe, and Standards-Compliant Testing

The automated, servo-controlled operation, complete with a microprocessor/PC-based control system, guarantees consistent, reliable results. Compliance with ASTM, ISO, and BIS standards, alongside integrated safety interlocks and an emergency stop, prioritizes operator safety and quality assurance in every test.

FAQs of Computerized Universal Testing Machine:

Q: How does the computerized universal testing machine ensure precise load measurement?

A: The machine utilizes a strain gauge-based load cell with a displacement resolution of 0.01mm. This advanced sensor technology provides highly accurate readings (1% of indicated load) for all testing processes, ensuring reliable results for tensile, compression, bending, and shear testing.Q: What testing standards are supported by this universal testing machine?

A: This machine is designed to meet and exceed major testing standards, incorporating ASTM, ISO, and BIS certification requirements. It assures users that each test conducted will align with recognized industry norms for material strength assessment.Q: When should I use the optional attachments like extensometers and compression platens?

A: Optional accessories such as extensometers and compression platens should be used when specific test types, like precise elongation measurement or compressive strength determination, are required. These attachments optimize the machines versatility for a wide variety of material samples and testing protocols.Q: Where can the universal testing machine be installed for optimal performance?

A: This machine is ideal for installation in material testing laboratories or industrial test departments. Its robust construction and adaptability to different environments allow consistent performance whether used in educational institutions, research labs, or quality control facilities.Q: What are the benefits of computerized and automated control in this testing machine?

A: Computerized and automated control systems enhance testing repeatability, minimize manual errors, and provide streamlined data collection. Users benefit from efficient workflows, programmable test parameters, and digital documentation for analysis and record keeping.Q: How are test results accessed and exported from the machine?

A: Results can be viewed on the digital LCD display or via a Windows-based software interface. Data can be exported easily through USB, RS232, or LAN connectivity, allowing users to save, share, and analyze results conveniently within their networked environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metallurgical Engineering Lab Instruments Category

Roll Crusher

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Material : Mild Steel

Surface Treatment : Paint Coated

Accuracy : High Precision

Application : Mining, Cement, Aggregate, and Power plants

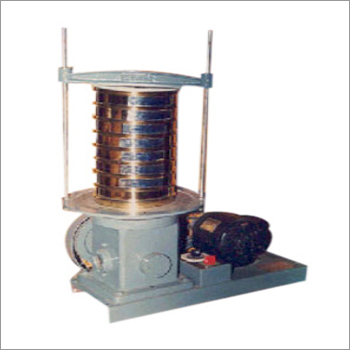

Sieve Shaker

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Material : Mild Steel Body with Stainless Steel Sieves

Surface Treatment : Powder Coated

Accuracy : High Precision with Consistent Results

Application : Soil, Aggregate, Cement, Chemical, Pharmaceutical and Powder Testing

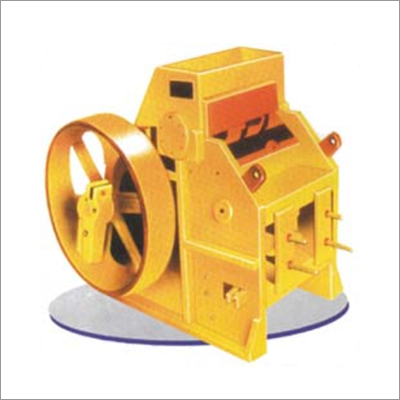

Jaw Crusher

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Material : Cast Iron & Mild Steel

Surface Treatment : Paint Coated

Accuracy : High crushing efficiency

Application : Mining, Construction, Metallurgy, Chemical Industries

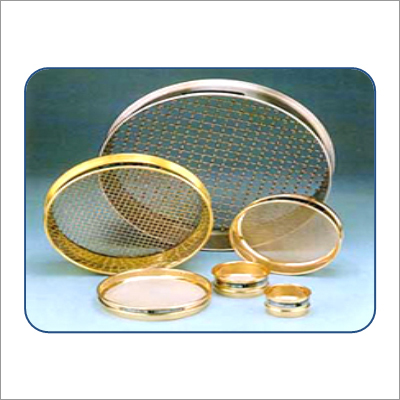

Test Sieves

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Material : Stainless Steel 304

Surface Treatment : Polished Stainless Steel

Accuracy : Precision manufactured to ASTM & ISO standards

Application : Soil, Aggregate, Chemical, Pharmaceutical Sampling

Factory Address :

Plot No 47, Emerald Indl Estate, Kidc Indl Area, Deku Village, Khalapur Taluk,

Khopoli Raigad, Maharahtra

Send Inquiry

Send Inquiry