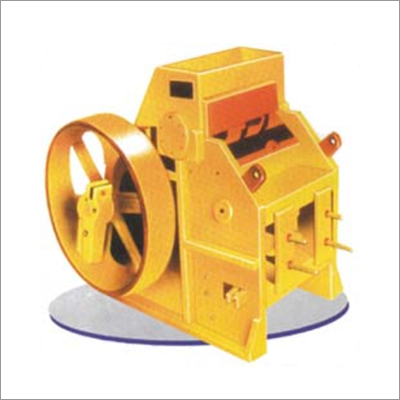

Jaw Crusher

Jaw Crusher Specification

- Accessories Type

- Jaw Plates, Flywheels, Toggle Plates

- Operating Pressure

- Normal atmospheric pressure

- Features

- Strong construction, Easy to operate and maintain, Long service life

- Accuracy

- High crushing efficiency

- Control System

- Manual/PLC Based

- Power Source

- Electric Motor

- Technology

- Mechanical crushing

- Surface Treatment

- Paint Coated

- Machine Type

- Heavy Duty Crusher

- Type

- Jaw Crusher

- Material

- Cast Iron & Mild Steel

- Function

- Crushing stones, ores, minerals

- Application

- Mining, Construction, Metallurgy, Chemical Industries

Jaw Crusher Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 04 Per Month

- Delivery Time

- 3-8 Week

About Jaw Crusher

Capitalizing on our talented workforce and sound amenities, we are ensure to manufacture and export a modern range of Jaw Crusher. These crushers are used in various industries including engineering, automotive and railway for efficient crushing of stone, coal, various minerals and ores. These Jaw Crusher is made and designed by our professionals as per the set industry norms using supreme grade materials. Furthermore, our crushers possess various characteristics such as hassle free performance, energy efficiency and rugged construction.

Further Details:

We are engaged in offering Crusher to our clients.

- Two series of Jaw Crushers are available.

- Single Toggle & Double Toggle Type.

- Both type of Jaw Crushers are available in high range of production capacity. These are supposed to be most economical with highest ratio of size reduction.

| Model | Size of Crusher mm | Max Feed | Motor HP | RPM |

|---|---|---|---|---|

| JP-0804 | 200 x 100 | 3" | 5 | 280 |

| JP-1006 | 250 x 150 | 5" | 10 | 280 |

| JP-1207 | 300 x 175 | 6" | 15 | 325 |

| JP-1609 | 400 x 225 | 8" | 25 | 325 |

| JP-2010 | 500 x 250 | 9" | 30 | 325 |

| JP-3009 | 750 x 225 | 8" | 30 | 325 |

| JP-3015 | 750 x 275 | 14" | 40 | 325 |

| JP-3608 | 900 x 200 | 7" | 50 | 300 |

| JP-3620 | 900 x 500 | 16" | 60 | 300 |

| JP-3624 | 900 x 600 | 21" | 75 | 300 |

Sturdy Construction for Demanding Applications

Built from premium cast iron and mild steel, this jaw crusher is designed to withstand intensive usage in mining, construction, metallurgy, and chemical sectors. Its resilient build, with a paint-coated finish, ensures longevity even in tough environments. The manganese steel jaw plates enhance its capability to process abrasive or hard materials, making it a reliable solution for large-scale and continuous operations.

Efficient Crushing and Adjustable Output

The jaw crusher ensures high crushing accuracy, processing feed up to 150 mm with a customizable discharge size between 10 and 40 mm. Its mechanical crushing technology, paired with easy-to-adjust settings, offers flexibility to meet precise requirements. Whether handling large rocks or finer materials, its efficiency caters to a wide range of applications and capacities, supporting various industry needs.

FAQs of Jaw Crusher:

Q: How does a jaw crusher achieve optimal crushing efficiency?

A: The jaw crusher utilizes mechanical crushing, where the material is compressed between a manganese steel moving jaw and a fixed jaw. This process breaks down large stones, ores, and minerals efficiently, resulting in a uniform discharge size. The robust construction ensures high efficiency over prolonged usage.Q: What benefits does the adjustable discharge size provide?

A: The adjustable discharge size, ranging from 10 to 40 mm, allows users to control the output according to the desired application. This flexibility is particularly beneficial in industries like mining and construction, where material specifications can vary according to project requirements.Q: When should the jaw plates and other accessories be replaced?

A: Jaw plates, toggle plates, and flywheels should be inspected regularly and replaced when significant wear, cracks, or chipping are noticed. Regular maintenance prolongs the machines service life and maintains high crushing efficiency. The replacement interval depends on material hardness and usage intensity.Q: Where can these jaw crushers be used effectively?

A: These jaw crushers are ideal for use in mining sites, construction zones, metallurgical operations, and chemical processing facilities. Their ability to handle various materials and heavy-duty performance makes them versatile across industries requiring primary crushing.Q: What is the process for adjusting the discharge size in this jaw crusher?

A: The discharge size can be adjusted manually or via a PLC-based control system, depending on the model. Adjusting the setting modifies the gap between the jaws, enabling users to achieve the desired output size for their specific material processing needs.Q: How is the jaw crusher operated and maintained?

A: Operation is straightforward due to its manual or optional PLC-based control system. Routine maintenance involves checking for wear on jaw plates and other accessories, cleaning, lubrication, and timely replacement of parts, all of which are facilitated by the crushers accessible design.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metallurgical Engineering Lab Instruments Category

Roll Crusher

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Application : Mining, Cement, Aggregate, and Power plants

Surface Treatment : Paint Coated

Machine Type : Heavy Duty Crusher

Technology : Double Roll Crushing

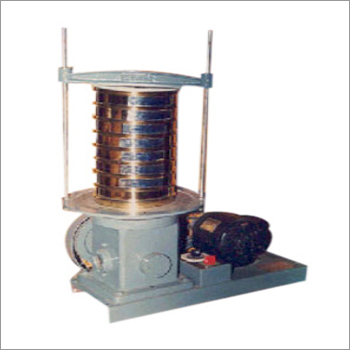

Sieve Shaker

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Application : Soil, Aggregate, Cement, Chemical, Pharmaceutical and Powder Testing

Surface Treatment : Powder Coated

Machine Type : Table Top

Technology : Electromechanical Vibratory

Riffle Sample Divider

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Application : Soil, cement, aggregates, and other powder/granular sample splitting

Surface Treatment : Polished & Painted

Machine Type : Laboratory Equipment

Technology : Manual Sampling

Hot Air Laboratory Oven

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Application : Laboratories, Research Centers, Industrial Testing

Surface Treatment : Powder Coated

Machine Type : Bench Top / Floor Mount

Technology : Hot Air Circulation

Factory Address :

Plot No 47, Emerald Indl Estate, Kidc Indl Area, Deku Village, Khalapur Taluk,

Khopoli Raigad, Maharahtra

Send Inquiry

Send Inquiry