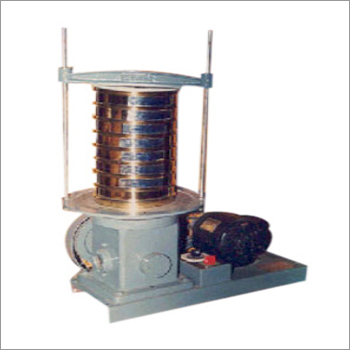

Sieve Shaker

Sieve Shaker Specification

- Features

- Compact design, Low Noise, Easy Operation, Durable Construction

- Surface Treatment

- Powder Coated

- Accuracy

- High Precision with Consistent Results

- Accessories Type

- Sieve Stack, Lid, Receiver

- Machine Type

- Table Top

- Automation Grade

- Semi-Automatic

- Operating Pressure

- Atmospheric

- Power Source

- Electric

- Control System

- Digital Timer Control

- Technology

- Electro-mechanical Vibratory

- Type

- Laboratory Sieve Shaker

- Material

- Mild Steel Body with Stainless Steel Sieves

- Function

- Particle Size Separation and Analysis

- Application

- Soil, Aggregate, Cement, Chemical, Pharmaceutical and Powder Testing

- Voltage

- 220-240 V AC

- Weight

- Approx. 45 kg

- Motor Power

- 0.25 HP

- Maintenance

- Low maintenance requirements

- Sieve Diameter

- 200 mm (8 inch standard)

- Amplitudes

- Adjustable vibration amplitude

- Operation Mode

- Continuous or Timed

- Max Sample Capacity

- Up to 2 kg per batch

- Number of Sieves Supported

- Up to 7 sieves

- Display Type

- Digital Timer Display

- Compliance

- IS 2386 (Part I), ASTM E11

- Noise Level

- < 75 dB

- Sieve Material

- 304 Stainless Steel Mesh

- Frequency Range

- 50 Hz

Sieve Shaker Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 04 Per Month

- Delivery Time

- 3-8 Week

About Sieve Shaker

We have attained the maximum satisfaction of our clients by manufacturing and exporting an extensive range of Sieve Shaker. These shakers are suitable for sieving of high density products and for dry and wet sieving analysis. Manufactured at our state of the art machining facility by employing quality tested materials, our Sieve Shaker is recognized for its accurate & noiseless performance, low maintenance and rugged construction. We adhere to the parameters of the national and international quality standards to provide the clients with utmost satisfaction in terms of quality.

Further Details:

The body of Sieve Shaking Machine is made of Cast Iron and the base is made of MS Sheet..Top rotating plate is made of Cast Aluminum complete with arrangement for fixing 8"/20cm. or 30cm.dia. sieves with lid and receiver.

Features

-

Brass Sieve Shaker

-

1/4 HP Motor CROMPTON for 220/230V A.C. supply.

-

Timer 0-60minutes is provided in the circuit.

-

Rotation of sieve stage 12 per minute.

-

Simultaneous tapping 500per minute.

-

Oil bath for machine parts.

-

Oil level indicator.

Precision Particle Separation for Diverse Applications

Tailored for laboratory environments, this sieve shaker supports up to 7 sieves and handles sample capacities up to 2 kg per run. The adjustable vibration amplitude ensures precise separation of particles, making it ideal for soil, cement, aggregate, and powder testing. The compact design and high-quality stainless steel mesh deliver consistent, repeatable results across various industries.

Reliable and User-Friendly Operation

Equipped with a digital timer display and electro-mechanical drive, this semi-automatic sieve shaker offers easy setup and operation. The continuous or timed operation modes give flexibility for different test procedures, while low noise output and durable construction ensure a comfortable and long-lasting user experience.

FAQs of Sieve Shaker:

Q: How does the Laboratory Sieve Shaker achieve precise particle size separation?

A: The device uses adjustable amplitude electro-mechanical vibrations to rapidly and uniformly separate particles through stacked stainless steel sieves, ensuring accurate and consistent analysis of sample materials.Q: What materials and industries can benefit from using this sieve shaker?

A: This laboratory sieve shaker is suitable for applications in soil, aggregate, cement, chemicals, pharmaceuticals, and other powder testing industries where precise particle size analysis is required.Q: When should I use the adjustable amplitude and timer controls?

A: Adjust the vibration amplitude based on the specific material being tested for optimal separation. Use the digital timer to set continuous or timed operation depending on your testing protocol and required duration.Q: Where should this sieve shaker be installed for optimal operation?

A: Install the unit on a stable laboratory tabletop, ensuring it is placed in a vibration-free, dry, and dust-free environment to maintain optimal performance and longevity.Q: What is the process for running a sample batch with this sieve shaker?

A: Stack up to 7 sieves in the unit, add your sample (up to 2 kg), secure the lid and receiver, set the desired amplitude and timer on the digital control, and initiate the shaking process. Once complete, collect and analyze the separated fractions.Q: What are the key benefits of using this particular sieve shaker?

A: Benefits include high precision, adjustable operation, low maintenance, digital timer control, low noise levels, and compliance with international standards, making it a reliable and efficient choice for laboratory analysis.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metallurgical Engineering Lab Instruments Category

Riffle Sample Divider

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Technology : Manual Sampling

Features : Corrosion resistant; Portable; Easy to clean and maintain; Supplied with interchangeable riffle boxes

Surface Treatment : Polished & Painted

Machine Type : Laboratory Equipment

Hot Air Laboratory Oven

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Technology : Hot Air Circulation

Features : Uniform Heat Distribution, Energy Efficient, Safety Lock, Over Temperature Protection

Surface Treatment : Powder Coated

Machine Type : Bench Top / Floor Mount

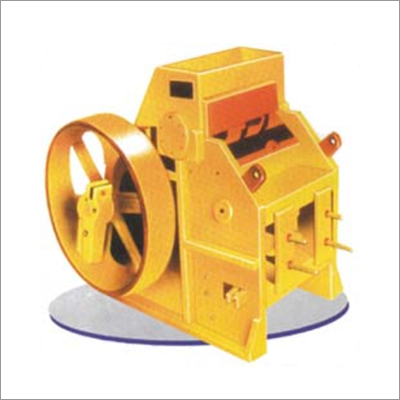

Jaw Crusher

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Technology : Mechanical crushing

Features : Strong construction, Easy to operate and maintain, Long service life

Surface Treatment : Paint Coated

Machine Type : Heavy Duty Crusher

Blaine's Apparatus-Average Particle Size Analyser

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Technology : Air Permeability Method

Features : Portable, easy to use and maintain, provides accurate measurement of particle fineness

Surface Treatment : Polished

Machine Type : Manual & Laboratory

Factory Address :

Plot No 47, Emerald Indl Estate, Kidc Indl Area, Deku Village, Khalapur Taluk,

Khopoli Raigad, Maharahtra

Send Inquiry

Send Inquiry