AUTOMATIC COMPUTERISED BRINELL HARDNESS TESTING

AUTOMATIC COMPUTERISED BRINELL HARDNESS TESTING Specification

- Features

- Automatic Loading & Unloading, Image Processing, Data Storage, Report Generation

- Gas Pressure

- Not Required

- Port Size

- Standard USB port

- Hardness

- Brinell (HBW 2.5/62.5 to HBW 10/3000)

- Operating Voltage

- 230V AC

- Equipment Type

- Computerized Brinell Hardness Testing Machine

- Max Height

- 250 mm (Specimen)

- Power Supply

- 230V AC, 50 Hz, Single Phase

- Frequency

- 50 Hz

- Mounting Type

- Floor Standing

- Application

- Metals, Alloys, Industrial Specimens Hardness Testing

- Accuracy

- 1% of Displayed Value

- Response Time

- < 1 sec to Display HB Value

- Resolution

- 0.1 HBW

- Display Type

- Digital with PC Interface (Windows Software)

- Temperature

- +10C to +40C (Operating)

- Interface Type

- USB/RS232 Connectivity

- Automation Grade

- Fully Automatic

- Number of Specimens

- Single Specimen per Test Cycle

- Usage

- Industrial/Metallurgical Laboratory

- Capacity

- 3000 kgf Standard (500 kgf, 750 kgf, 1000 kgf, 1500 kgf, 3000 kgf selectable)

- Test Speed

- 120 mm/min

- Test Width

- 200 mm

- Test Stroke

- 100 mm

AUTOMATIC COMPUTERISED BRINELL HARDNESS TESTING Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 04 Units Per Month

- Delivery Time

- 3-8 Week

About AUTOMATIC COMPUTERISED BRINELL HARDNESS TESTING

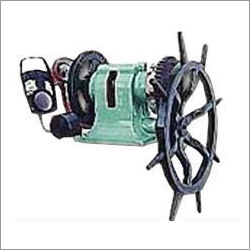

AUTOMATIC COMPUTERISED BRINELL HARDNESS TESTING MACHINE

Machine Confirm to IS 2281/2005, BS : 240 & ASTM E-10.

Automatic spindle up & down.

Dwell time setting.

Measuring range up to 6 mm diameter.

Fully computerized system for indentation measurement & display. Accurate measurement of Brinell Hardness through

matched Optics, CCD Camera, hardware and software using advanced image processing technology.Windows based software system with well managed database. Windowing facility provided for measurements of bad

images due to poor surface finish and other reasons.Operating modes: 1) Automatic mode 2) Measuring mode 3) Manual mode.

Cutting-Edge Brinell Hardness Testing

Engineered for high-throughput environments, this computerized machine streamlines the hardness testing process for metals and alloys. With quick response times and selectable load capacities up to 3000 kgf, users experience optimal versatility. The floor-standing device is designed for maximum reliability, featuring automatic safety controls and compatibility with Windows-based data analysis via USB or RS232.

Efficient Data Management & Reporting

Store up to 10,000 test records and generate professional reports in PDF or Excel format for seamless documentation. The integrated image processing and digital display ensure easy result interpretation. Export data through standard USB ports with high security and traceability, supporting modern laboratory workflows and industrial quality assurance.

Superior Accuracy and Compliance

Combining accuracy within 1% of displayed value and compliance with international testing standards (IS 1500, ASTM E10, BS 240, ISO 6506), the equipment guarantees reliable hardness measurements. Automatic and manual calibration settings maintain consistent performance, while safety features like overload protection and emergency stop safeguard both users and specimens.

FAQs of AUTOMATIC COMPUTERISED BRINELL HARDNESS TESTING :

Q: How does the automatic Brinell hardness tester perform the hardness measurement?

A: The machine uses a tungsten carbide ball indenter to apply a selectable load to a single specimen. It automatically carries out loading, unloading, and indentation measurement using image processing software, ensuring precise and rapid results.Q: What calibration facilities are available with this equipment?

A: Users can choose between automatic and manual calibration modes, ensuring consistent accuracy and adherence to standards with minimal effort for routine or advanced calibrations.Q: When should I export test reports and what formats are supported?

A: You can export test reports immediately after each test or periodically as required. The machine supports PDF and Excel formats, allowing easy integration with documentation and quality management systems.Q: Where is the data stored and what is the maximum storage capacity?

A: Test data is stored digitally within the machines built-in memory. You can save up to 10,000 test records, ensuring secure retention and easy retrieval for audits or analysis.Q: What safety features are integrated into the hardness tester?

A: The equipment includes overload protection to prevent damage and an emergency stop to quickly halt operations in case of any irregularities, fostering a safe working environment for users.Q: What benefits does automatic computerized operation offer for industrial hardness testing?

A: Automatic operation enhances efficiency and repeatability, minimizing human error. Digital display and export functions streamline workflows, while compliance with global standards and rapid response times ensure reliability and precision.Q: How is the machine connected to a PC for data analysis and report generation?

A: Connection is established via standard USB and RS232 interfaces, enabling seamless communication with Windows-based software for data management, report generation, and in-depth analysis.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Equipments Category

OPTICAL BRINELL HARDNESS TESTING MACHINE

Price Range 10000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Features : High accuracy, Durable body, Manual/optical measuring

Capacity : 3000 kgf (30 kN)

Mounting Type : Floor mounted

Machine Weight : Approx. 450 kg

ANALOG CHARPY / IZOD IMPACT TESTING MACHINE

Price Range 10000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Dual test support (Charpy & Izod), Robust construction

Capacity : 300 Joules (Charpy) / 170 Joules (Izod)

Mounting Type : Floor Mounted

Machine Weight : Approx. 120 kg

ERICHSEN CUPPING TESTING MACHINE

Price Range 10000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Ergonomic Handwheel, Robust Construction, Adjustable Clamping Force

Capacity : Up to 45 kN

Mounting Type : Bench top

Machine Weight : Approx. 65 kg

Analogue UTM

Price Range 10000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Overload protection, rugged frame, adjustable crosshead

Capacity : 100 kN

Mounting Type : Floor Mounted

Machine Weight : Approx. 550 kg

Factory Address :

Plot No 47, Emerald Indl Estate, Kidc Indl Area, Deku Village, Khalapur Taluk,

Khopoli Raigad, Maharahtra

Send Inquiry

Send Inquiry