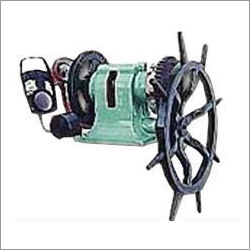

ERICHSEN CUPPING TESTING MACHINE

ERICHSEN CUPPING TESTING MACHINE Specification

- Specimen Size

- Max. 100 x 100 mm

- Temperature

- 10C 40C (operating)

- Power Supply

- 230 V AC, 50 Hz

- Resolution

- 0.01 mm

- Features

- Ergonomic Handwheel, Robust Construction, Adjustable Clamping Force

- Humidity

- Up to 85% RH

- Number of Specimens

- Single specimen at a time

- Max Height

- 430 mm (Machine Height)

- Accuracy

- 0.05 mm

- Application

- Paint, Coating & Sheet Metal Cupping Tests

- Mounting Type

- Bench top

- Frequency

- 50 Hz

- Test Range

- 0 12 mm cupping depth

- Measuring Range

- 0 12 mm

- Response Time

- Instantaneous mechanical response

- Equipment Type

- Cupping Testing Machine

- Operating Voltage

- 230 V

- Usage

- Testing ductility of metals

- Capacity

- Up to 45 kN

- Machine Weight

- Approx. 65 kg

- Test Speed

- 0.1 10 mm/min (adjustable)

- Test Width

- Sample diameter up to 90 mm

- Test Stroke

- Up to 30 mm

- Control Mode

- Manual and Motorized

ERICHSEN CUPPING TESTING MACHINE Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 04 Units Per Month

- Delivery Time

- 3-8 Week

About ERICHSEN CUPPING TESTING MACHINE

ERICHSEN CUPPING TESTING MACHINE

This Machine is designed to reveal the cupping qualities of metal sheets and strips . It can be used for testing the adhesion, elasticity and porosity of coats of paints or varnish by way of comparison.

The dimensions and tolerances of various machine parts and the test requirements conform to IS: 1956-1974.

FEATURES :

The appearance of the material after fracture gives an indication of the grain structure of the material and also of its constitution to same extent.

L.C. of micrometer device is 0.01mm

Efficient and Versatile Material Testing

Engineered for versatility, this cupping test apparatus supports both manual and motorized operation modes, giving users precise control over test parameters such as speed and clamping force. Compatible with a range of materialsincluding mild steel, stainless steel, and aluminumthe system offers accurate results across various sample sizes and cupping depths. The bench-top robust construction ensures long-term reliability for manufacturers, suppliers, and exporters in quality control labs.

Safety-First Design with User-Friendly Features

The ERICHSEN Cupping Testing Machine prioritizes operator safety through its protective enclosure and ergonomic handwheel. Its intuitive controls and adjustable settings minimize user error while the safety shield reduces risks during operation. The machine is supplied with key accessories, including a test dial indicator and sample cutting template, further streamlining the testing workflow.

Adaptable Performance for Laboratory and Field Use

Offering a field-serviceable design and a calibration certificate upon request, the machine can be maintained easily for extended use. With adjustable test speeds and sample clamping force, and a broad operational temperature and humidity range, it is ideal for rigorous industrial environments or research laboratories. Its robust construction and portable, bench-top mounting make it a preferred choice for material testing professionals.

FAQs of ERICHSEN CUPPING TESTING MACHINE:

Q: How does the Erichsen Cupping Testing Machine perform material ductility tests?

A: The machine evaluates the ductility of metal sheets by incrementally pressing a hemispherical punch until a visible crack forms, measuring the materials resistance to deformation. The process is monitored using an instant-response mechanical dial indicator, providing accurate cupping depth results.Q: What materials can be tested with this machine?

A: This cupping tester is compatible with mild steel, stainless steel, and aluminum sheets, accommodating a wide variety of applications in the coatings, paint, and sheet metal industries.Q: When should the adjustable clamping force be used during testing?

A: The adjustable clamping force ensures the specimen remains securely positioned during testing, preventing slippage or inaccurate results. It should be set based on the materials thickness and hardness before each test cycle.Q: Where is it suitable to install and operate the cupping testing machine?

A: This equipment is designed for bench-top installation in laboratories, quality control departments, and research facilities. Its robust build and protective enclosure allow safe use in both industrial and academic environments.Q: What is the process for calibrating the machine, and is a certificate provided?

A: Calibration is performed using supplied or external standards to ensure measurement accuracy. A calibration certificate is available upon request, confirming the machines compliance with industry accuracy requirements.Q: How can users benefit from the field-serviceable and robust construction?

A: The field-serviceable design allows for easy on-site maintenance and servicing, reducing downtime. The powder-coated, robust construction enhances durability, ensuring reliable long-term performance in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Equipments Category

FATIGUE TESTING MACHINE

Price Range 10000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Test Width : Standard (As per IS standard specimens)

Response Time : Instantaneous upon fracture

Usage : Metallurgical Laboratories, Research

Hardness : Machine: CNC Hardened components

Mechanical Brinell Hardness Tester

Price Range 10000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Test Width : Up to 100 mm

Response Time : Immediate

Usage : Laboratory, industrial material testing

Hardness : Brinell scale

DIGITAL CHARPY / IZOD IMPACT TESTING MACHINE

Price Range 10000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Test Width : 10 mm

Response Time : Instantaneous

Usage : Metallurgical laboratories, Quality control

Hardness : Standard impact hammer, hardened to required specification

AUTOMATIC COMPUTERISED BRINELL HARDNESS TESTING

Price Range 10000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Test Width : 200 mm

Response Time : < 1 sec to Display HB Value

Usage : Industrial/Metallurgical Laboratory

Hardness : Brinell (HBW 2.5/62.5 to HBW 10/3000)

Factory Address :

Plot No 47, Emerald Indl Estate, Kidc Indl Area, Deku Village, Khalapur Taluk,

Khopoli Raigad, Maharahtra

Send Inquiry

Send Inquiry