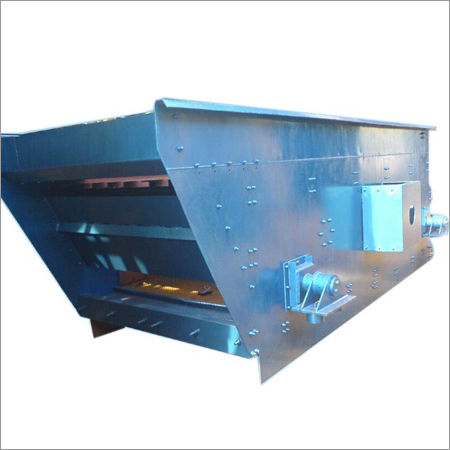

Linear Motion Vibro Screen

Linear Motion Vibro Screen Specification

- Accessories Type

- Sieve Decks & Meshes

- Power Source

- Electric

- Surface Treatment

- Powder Coated / Painted / Polished

- Accuracy

- High precision screening (up to 99.5%)

- Control System

- PLC / Manual

- Operating Pressure

- Atmospheric

- Technology

- Linear Vibratory Screening

- Machine Type

- Linear Motion Sifter

- Type

- Vibro Screen

- Material

- Mild Steel / Stainless Steel

- Function

- Separation, Grading, Sifting, Screening

- Application

- Pharmaceutical, Chemical, Food Processing, Minerals, Ceramics, Agriculture, Plastics

Linear Motion Vibro Screen Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 04 Per Month

- Delivery Time

- 3-8 Week

About Linear Motion Vibro Screen

We are engaged in manufacturing and supplying Linear Motion Vibro Screen with the vision to offer advanced and premium quality products to our clients. These screens are used for effective removal of dust particles and over-sized particles from the grains. Our Linear Motion Vibro Screen is designed and manufactured by our professionals as per the set industry norms using supreme grade materials to ensure easy installation, low maintenance and superior performance. For efficient triple deck separation and grain cleaning, our screens are equipped with vibro motors. We offer these screens at a nominal price.

Application:

Vibratory Screening equipment equipped with Vibro motors for efficient screening of grains upto triple deck separation. The equipment is suitable to handle upto 3mm dry grains. The amplitude of vibration is adjustable through counter weights of Vibro-motors.

Capacity available:

0.5 TPH - 100 TPH.

Versatile Screening Capabilities

The Linear Motion Vibro Screen supports a broad spectrum of applications, thanks to its multiple deck options and precise mesh range. Its customizable inlet size and high screening accuracy make this equipment suitable for fine to coarse material separation, sifting, and grading tasks in industries such as pharmaceuticals, chemicals, food, and minerals.

Robust Design with Flexible Material Choices

Users can select frame materials including Mild Steel, SS304, or SS316 depending on hygiene and process requirements. The machines surface treatments, such as powder coating, painting, or polishing, ensure long-term performance, corrosion resistance, and compatibility with varied applications.

Efficient and Customizable Performance

Driven by vibratory motors with adjustable power from 0.5 HP to 5 HP, the Linear Motion Vibro Screen handles various processing volumes. Whether operated manually or via PLC, it guarantees consistent, energy-efficient, and reliable operation, tailored to the demands of high-volume or specialized production.

FAQs of Linear Motion Vibro Screen:

Q: How does a Linear Motion Vibro Screen operate?

A: A Linear Motion Vibro Screen works by generating linear vibrations through vibratory motors mounted on the machine. This precise movement enables efficient separation, grading, and sifting of materials based on particle size, as they travel across single or multiple decks fitted with customized mesh sizes.Q: What industries can benefit from using this type of vibro screen?

A: This machine serves a wide range of industries, including pharmaceuticals, chemicals, food processing, minerals, ceramics, agriculture, and plastics. Its adaptability to different materials and hygienic construction makes it valuable for both raw material and finished product screening.Q: When should I choose a multi-deck screen configuration?

A: A multi-deck configuration is ideal when you require multiple product separations or gradings from a single feed. This setup enables simultaneous classification into several particle size fractions, thus improving process efficiency and throughput.Q: Where is the Linear Motion Vibro Screen typically installed within a process line?

A: Typically, the Vibro Screen is installed after initial size reduction or mixing stages and before packaging, blending, or further processing. It ensures that only the desired material sizes progress, improving product quality and consistency.Q: What is the process for customizing inlet size and choosing the appropriate mesh?

A: Customization begins with a thorough assessment of your material properties, capacity requirements, and application specifics. Experts guide you in determining the ideal inlet size and selecting a mesh between 16 and 200, ensuring optimal separation and high-precision screening accuracy.Q: How does the vibro screen improve operational benefits for manufacturers?

A: Manufacturers experience enhanced productivity with high screening speeds, reduced manual intervention, and minimal maintenance due to robust construction. The technology ensures up to 99.5% screening accuracy, leading to superior product quality and reduced waste.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SCREENING MACHINERY Category

Gyratory Motion Screen

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Control System : Electric control panel

Power Source : Electric

Accuracy : High separation efficiency

Material : Mild steel / Stainless steel

Circular Motion Vibro Screen

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Control System : Electronic Control Panel

Power Source : Electric

Accuracy : High Precision Screening

Material : Stainless Steel

Factory Address :

Plot No 47, Emerald Indl Estate, Kidc Indl Area, Deku Village, Khalapur Taluk,

Khopoli Raigad, Maharahtra

Send Inquiry

Send Inquiry