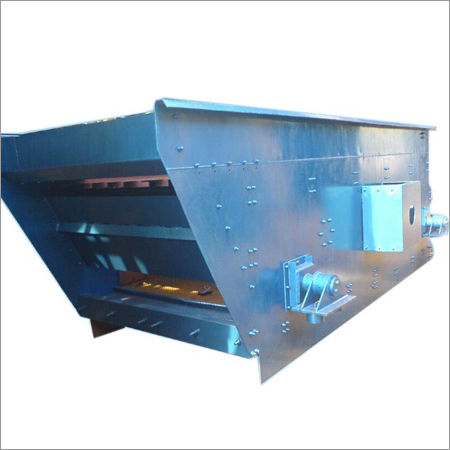

Gyratory Motion Screen

Gyratory Motion Screen Specification

- Machine Type

- Vibratory / Gyratory sieve

- Accuracy

- High separation efficiency

- Accessories Type

- Mesh screens, Deck frames, Drive motor

- Control System

- Electric control panel

- Operating Pressure

- Atmospheric

- Surface Treatment

- Powder coated

- Technology

- Gyratory motion screening

- Power Source

- Electric

- Type

- Screening equipment

- Material

- Mild steel / Stainless steel

- Function

- Separation, Grading, Sifting

- Application

- Minerals, Chemicals, Food processing, Fertilizers, Sand, etc.

- Voltage

- 220V / 380V

Gyratory Motion Screen Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 04 Per Month

- Delivery Time

- 3-8 Week

About Gyratory Motion Screen

We have embossed a dynamic niche in both the domestic and international markets by manufacturing and exporting a superior range of Gyratory Motion Screen. Made and designed using optimum quality MS and SS at our state of the art machining facility, these screens are suitable to separate super fine materials below 3mm from grains. Easy installation, energy efficiency and superior performance are some of the characteristics of our Gyratory Motion Screen. In addition, we are capable of customizing these screens as per the needs of the clients.

Application:

Vibratory screening equipment equipped with Vibro Motor delivers gyratory motion through centrifugal unbalanced force on the circular decks mounted on multiple springs. Suitable to separate super fine materials below 3mm. The equipment available with anti blinding elements. Body construction available in GMP standard.

Capacity available:

50Kgs/Hr - 2000Kgs/hr.

Customizable Screening Solutions

The Gyratory Motion Screen offers versatility with its single to multiple deck options and adjustable mesh sizes, allowing it to adapt to your specific separation or grading needs. Whether processing minerals, chemicals, or food products, the design can be tailored to suit different operational capacities and product types, ensuring optimal performance in every application.

Efficient and Reliable Operation

Equipped with a high-performance vibratory drive mechanismeither by vibratory motor or eccentric weightsthis screening equipment ensures aggressive but controlled material motion. The electric control panel provides seamless operation, while multiple discharge outlets enable streamlined sorting for enhanced productivity and efficiency.

Durable Construction for Varied Applications

Manufactured from either mild steel or stainless steel, and finished with a robust powder coating, the Gyratory Motion Screen withstands challenging industrial environments. Its strong construction, combined with atmospheric pressure operation and compatibility with up to 60C, makes it a reliable asset for both heavy-duty and sensitive production lines.

FAQs of Gyratory Motion Screen:

Q: How does the Gyratory Motion Screen separate different grades of material?

A: The screen uses gyratory motion combined with customized mesh sizes and deck configurations to separate materials based on size. Feed material is efficiently stratified and directed to the designated outlets for each grade, ensuring precise separation and grading.Q: What types of industries benefit from using this screening equipment?

A: This equipment is widely used in industries such as mineral processing, chemicals, food processing, fertilizers, and sand production, where accurate separation, sifting, and grading of bulk materials are essential.Q: When should I opt for single, double, or multiple deck configurations?

A: The choice of deck configuration depends on the number of size fractions you need to separate. Single decks are ideal for basic separation, while double and multiple decks allow for simultaneous grading of multiple product sizes in one operation.Q: Where can I install the Gyratory Motion Screen within my facility?

A: The screen is designed for flexible installation within production lines or standalone setups. Its compact yet robust structure makes it suitable for various plant layouts and industrial environments, as long as proper electric and space provisions are in place.Q: What is the process for customizing the mesh size and screen area?

A: Mesh size and screen area can be specified at the time of order, based on your material characteristics and desired throughput. Our team collaborates with clients to select optimal configurations ensuring high separation efficiency.Q: How is the equipment maintained and what accessories are necessary for operation?

A: Routine maintenance involves checking mesh screens, deck frames, and the drive motor for wear. Essential accessories include replacement mesh screens, deck frames, and a reliable power connection to the electric control panel for consistent usage.Q: What are the main benefits of using a Gyratory Motion Screen compared to conventional sieves?

A: This screen offers higher separation accuracy, multiple simultaneous grading options, customizable performance features, and robust construction, which together result in improved process efficiency and lower operational downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SCREENING MACHINERY Category

Linear Motion Vibro Screen

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Control System : PLC / Manual

Material : Mild Steel / Stainless Steel

Operating Pressure : Atmospheric

Technology : Linear Vibratory Screening

Circular Motion Vibro Screen

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Control System : Electronic Control Panel

Material : Stainless Steel

Operating Pressure : Atmospheric

Technology : Vibratory Screening

Factory Address :

Plot No 47, Emerald Indl Estate, Kidc Indl Area, Deku Village, Khalapur Taluk,

Khopoli Raigad, Maharahtra

Send Inquiry

Send Inquiry