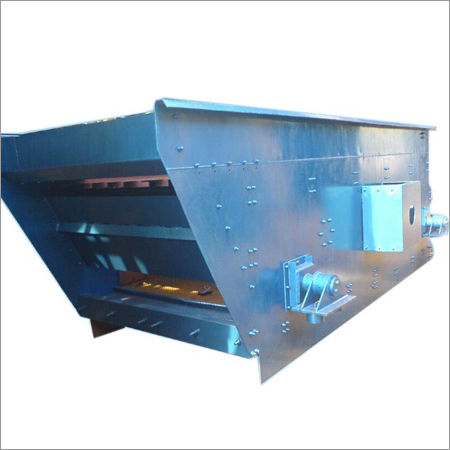

Circular Motion Vibro Screen

Circular Motion Vibro Screen Specification

- Surface Treatment

- Polished

- Automation Grade

- Automatic

- Machine Type

- Automatic Screening Machine

- Technology

- Vibratory Screening

- Accuracy

- High Precision Screening

- Power Source

- Electric

- Control System

- Electronic Control Panel

- Operating Pressure

- Atmospheric

- Type

- Circular Motion Vibro Screen

- Material

- Stainless Steel

- Function

- Separation and Grading of Materials

- Application

- Food, Chemical, Pharmaceutical, and Mineral Industries

Circular Motion Vibro Screen Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 04 Per Month

- Delivery Time

- 3-8 Week

About Circular Motion Vibro Screen

Incorporated in the year 1999, we are committed to manufacture and export an exceptional range of Circular Motion Vibro Screen. These screens are made by a team of skilled professionals using premium quality materials, following the norms and guidelines laid down by the industry. Featured with easy installation, low maintenance and superior performance, our Circular Motion Vibro Screen is suitable for handling different grain of upto 3mm length. In addition, we are capable of customizing these screens as per the needs of the clients.

Application:

Vibratory Screening equipment with counter-weight mechanism mounted on Drive Shaft to adjust the amplitude of Vibration. Available upto 4 deck separation with wide range of capacity.

Capacity available: 1TPH - 300TPH.

Versatile Screening for Multiple Industries

Our Circular Motion Vibro Screen delivers efficient, high-precision screening, making it ideal for applications across food, chemical, pharmaceutical, and mineral industries. Designed to meet varied throughput and separation needs, the robust construction and customizable options ensure seamless integration into any production process, boosting efficiency and product quality.

Customizable to Your Specifications

With options for screen diameter, deck quantity, material construction, and screen opening size, this machine is tailored to user needs. The discharge outlet and motor power can also be specified, guaranteeing optimal performance regardless of the application or industry needs.

Engineered for Reliable, Automatic Operation

This circular vibro screen boasts an electronic control panel, atmospheric operating pressure, and a vibratory drive mechanism for stable, consistent operation. Its automated processes minimize human intervention, thus enhancing safety and delivering dependable results for continuous production environments.

FAQs of Circular Motion Vibro Screen:

Q: How does the Circular Motion Vibro Screen separate materials during operation?

A: The Circular Motion Vibro Screen uses a vibratory motion produced by an unbalanced motor to induce movement in the screening surface. Materials fed onto the screen are spread evenly, and particles are separated according to the chosen screen opening size, allowing precise grading over single, double, or multiple decks.Q: What industries commonly use this vibro screen, and why is it beneficial?

A: This vibro screen is widely used in the food, chemical, pharmaceutical, and mineral industries. Its ability to provide high-precision separation and customizable configurations makes it invaluable for ensuring uniform product quality and enhancing process efficiency.Q: When should multiple decks be used in the screening process?

A: Multiple decks are recommended when separation of materials into more than two size fractions is required. Each deck can have a different mesh size, enabling simultaneous multi-stage grading and enhancing production throughput.Q: Where can this machine be installed within a processing facility?

A: The Circular Motion Vibro Screen can be placed inline within various stages of a processing plant, typically before or after other material handling equipment like conveyors, mixers, or packaging machines. Its compact, automatic design allows flexible installation in new or existing setups.Q: What is the recommended process for cleaning and maintaining the vibro screen?

A: Routine cleaning involves removing any residual materials from the screen surface and decks, preferably after each production cycle. Periodic checks of the motor, gaskets, and deck fastenings are advisable to ensure optimal performance and maximize machine lifespan.Q: How does the electronic control panel enhance machine operation?

A: The electronic control panel allows precise regulation of motor speed, operational timing, and other parameters, ensuring consistent screening accuracy. This level of control enables seamless automation and quick adaptation to different material processing requirements.Q: What are the customization options for discharge outlets and screen openings?

A: Discharge outlets and screen opening sizes can be tailored based on application needs. Customers can select specific outlet shapes, sizes, and orientations, as well as screen openings starting from 0.2 mm onwards, to ensure optimal product flow and targeted material separation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SCREENING MACHINERY Category

Gyratory Motion Screen

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Material : Mild steel / Stainless steel

Technology : Gyratory motion screening

Type : Screening equipment

Accuracy : High separation efficiency

Linear Motion Vibro Screen

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Material : Mild Steel / Stainless Steel

Technology : Linear Vibratory Screening

Type : Vibro Screen

Accuracy : High precision screening (up to 99.5%)

Factory Address :

Plot No 47, Emerald Indl Estate, Kidc Indl Area, Deku Village, Khalapur Taluk,

Khopoli Raigad, Maharahtra

Send Inquiry

Send Inquiry