Compression Testing Machine

Compression Testing Machine Specification

- Accuracy

- 1% of indicated load

- Surface Treatment

- Powder Coated

- Features

- Robust Structure, Easy Operation, High Precision

- Operating Pressure

- Up to 2000 kN (varies by model)

- Machine Type

- Analog/Digital

- Technology

- Hydraulic

- Control System

- Hand Operated / Digital Control Panel

- Power Source

- Electric

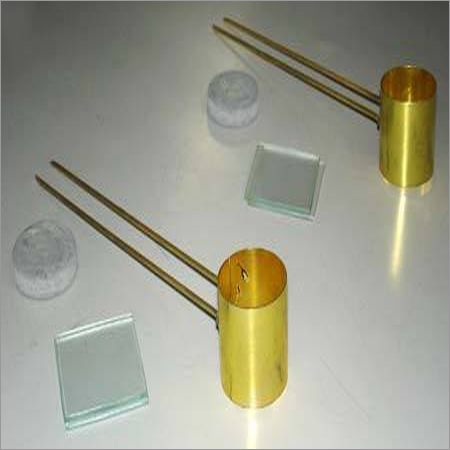

- Accessories Type

- Pressure Gauge, Platens, Spacers

- Automation Grade

- Semi-Automatic

- Type

- Compression Testing Machine

- Material

- Mild Steel

- Function

- Measuring compressive strength of materials

- Application

- Construction, Material Testing Laboratories, Civil Engineering

- Voltage

- 220-240 V AC, 50 Hz

- Ram Diameter

- 165 mm (typical)

- Max. Capacity

- Up to 2000 kN

- Display Type

- Analog or Digital (Optional)

- Weight

- Approx. 600-800 kg (depends on model)

- Color

- Blue/Customization Available

- Safety Features

- Overload Protection

- Operating Temperature

- +5°C to +40°C

- Piston Stroke

- 50 mm - 100 mm

- Loading Unit

- Four Pillar Construction

Compression Testing Machine Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 04 Per Month

- Delivery Time

- 3-8 Week

About Compression Testing Machine

A Compression Testing Machine is designed for testing materials under compression bending, shear loads, and transverse. With the help of this machine, hardness test on metals can also be conducted. We manufacture and supply the best quality Compression Testing Equipment in the market. We ensure our customers 100 percent satisfaction. The machines can be supplied in two variants that is hand operated and motorized.Available Models :

- 500kN

- 1000kN

- 2000kN

- 3000kN

Versatile Testing Capabilities

Designed for materials testing in construction and civil engineering, this machine accurately assesses the compressive strength of samples. With a high maximum capacity and adjustable ram diameter and piston stroke, it accommodates various specimen requirements, meeting laboratory standards and industry regulations.

Precision and Safety Features

The machine integrates advanced hydraulic technology and sensitive overload protection, delivering measurement accuracy within 1% of the indicated load. Its heavy-duty design maintains consistent performance, while user-friendly controls facilitate efficient and secure operation during every testing sequence.

Durable and Customizable Construction

Constructed from high-quality mild steel and finished with a powder coating, the machine is both robust and corrosion-resistant. Optional color customization is available to match laboratory preferences or corporate branding, ensuring seamless integration into your testing workflow.

FAQs of Compression Testing Machine:

Q: How does the compression testing machine operate to measure the compressive strength of materials?

A: This machine applies a controlled hydraulic force using a hand-operated or digital control panel, gradually compressing the test specimen between pressure plates. The built-in display (analog or digital) records the maximum load at failure, which determines the materials compressive strength.Q: What type of samples can be tested with this machine and in what settings is it typically used?

A: It is designed to test concrete, bricks, and similar construction materials. Commonly used in construction sites, civil engineering laboratories, and research facilities, the machine is ideal for material quality assessment and compliance verification.Q: When is maintenance required for the compression testing machine?

A: Routine maintenance is recommended after a certain number of tests or as specified by the manufacturer. Regular checks of hydraulic components, calibration, and inspection for wear are essential to ensure ongoing accuracy and safety.Q: Where can this machine be installed and what are its space requirements?

A: Due to its substantial weight (approximately 600-800 kg) and dimensions, it should be installed on a solid, level surface in a controlled laboratory or workshop environment. Adequate ventilation and power (220-240 V AC, 50 Hz) are necessary for optimal operation.Q: What is the process for setting up and using the machine?

A: Setup involves positioning the specimen between the platens, adjusting spacers if needed, and selecting the appropriate operating mode (analog or digital). After initializing, the test is started by applying hydraulic pressure until the specimen ruptures. The result is recorded through the display panel.Q: What are the primary benefits of using this compression testing machine?

A: Users benefit from high accuracy (1%), simple operation, enhanced safety via overload protection, and reliable performance due to its robust mild steel construction and powder-coated finish. These features ensure precise, repeatable results for material strength assessments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Engineering Instruments Category

Tile Flexure Testing Machine

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Function : Flexural/Bending Strength Test of Tiles

Accuracy : 1% of Indicated Load

Surface Treatment : Powder Coated Finish

Technology : Manual Mechanical Loading

Automatic Compactor

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Function : Soil Sample Preparation

Accuracy : High Precision Compaction

Surface Treatment : Powder Coated

Technology : Automatic Compaction Mechanism

Le Chatelier Mould

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Function : Measurement of Cement Expansion

Accuracy : High

Surface Treatment : Polished Finish

Technology : Precision Casting

Humidity Chamber

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Function : Control and maintain humidity & temperature

Accuracy : 2% RH, 1C

Surface Treatment : Powder Coated Finish

Technology : Hot Air Circulation

Factory Address :

Plot No 47, Emerald Indl Estate, Kidc Indl Area, Deku Village, Khalapur Taluk,

Khopoli Raigad, Maharahtra

Send Inquiry

Send Inquiry