Optical Brinell Hardness Tester

Optical Brinell Hardness Tester Specification

- Temperature

- 10C to 35C

- Hardness

- Brinell scale

- Accuracy

- Complies to IS:2281, BS:240, ASTM:E10

- Specimen Size

- Maximum 200 mm height

- Operating Voltage

- 220V AC

- Features

- Precise load application, robust construction, optical measurement

- Number of Specimens

- 1 at a time

- Resolution

- 0.001 mm

- Humidity

- 85%

- Frequency

- 50 Hz

- Port Size

- Standard: 10 mm

- Power Supply

- 220V AC, 50Hz

- Equipment Type

- Brinell Hardness Tester

- Test Range

- 8 to 650 HB

- Application

- Metals Hardness Measurement

- Max Height

- 200 mm

- Mounting Type

- Bench/Stand Mounted

- Response Time

- Immediate (manual observation)

- Usage

- Laboratory, Industrial

- Capacity

- 3000 kgf

- Machine Weight

- 145 kg approx

- Test Speed

- 0.05 mm/sec

- Test Width

- 68 mm

- Test Stroke

- 200 mm

Optical Brinell Hardness Tester Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 04 Units Per Month

- Delivery Time

- 3-8 Week

About Optical Brinell Hardness Tester

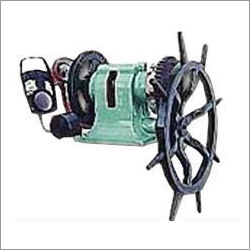

Optical Brinell Hardness Tester

Our highly experienced and professional team of experts enables us in offering a superior array of Optical Brinell Hardness Tester. These testers are designed for brinell hardness measurement on steel, ferrous material & also on non-ferrous material like brass, bronze and aluminum. Our Optical Brinell Hardness Tester is manufactured in accordance with international mechanical standards using optimum grade materials. These testers are tested by the experts before the final dispatch in order to make sure that they perform flawlessly.

Features

AATOUS has developed Brinell Hardness Testing Machine with optical device. Basic machine design and operation is similar to simple Hydraulically operated Brinell Tester But, with built - in optical device with 14 X magnification provided in front to project diameter of ball impression on glass screen with a micrometer measuring system with 0.01 mm least count. In this machine the indentor swivells and projects diameter of ball impression immediately after unloading operation which avoids additional time for measurement of ball impression. This is a production testing machine. This is suitable for foundry, forging shops, heat treatment shops, engineering institutions etc.

Robust Construction, Superior Accuracy

Engineered with a heavy-duty casting frame, this tester ensures minimal vibration and maximum stability during tests. The inclusion of a precision micrometer stage and a high quality microscope allows for accurate optical measurements, achieving a fine resolution of 0.001 mm. These features collectively enhance measurement reliability and repeatability for diverse metal specimens.

Comprehensive Testing Capability

This device offers a wide testing range (8 to 650 HB) and supports various load steps from 500 kgf up to 3000 kgf. Interchangeable indenter balls in 2.5mm, 5mm, and 10mm diameters add flexibility, making it suitable for a broad array of metals. Its design accommodates specimens up to 200 mm in height, fulfilling both laboratory and industrial applications.

User-Friendly and Certified Operation

Equipped with overload protection, adjustable sample support table, and manual reading with an option for digital documentation, this machine simplifies the hardness testing process. Each unit is accompanied by a calibration certificate and complies strictly with international standards (IS2281, ASTM E10, BS 240), ensuring trustworthy results for quality assurance.

FAQs of Optical Brinell Hardness Tester:

Q: How does the Optical Brinell Hardness Tester measure metal hardness?

A: The tester applies a controlled load through a hardened steel or tungsten carbide ball indenter onto the metal sample. The resulting indentation is examined using a high quality 20x microscope, and the diameter is measured for hardness calculation. This optical measurement ensures precision in evaluating hardness according to Brinell standards.Q: What is the process for using the optical measurement head?

A: To use the optical measurement head, position the sample on the adjustable table, select the desired load, and initiate the test. After indentation, focus the included microscope with the micrometer stage on the impresssion, measure its diameter manually or document digitally, and interpret the hardness value from Brinell charts.Q: When should calibration be performed and is a certificate included?

A: Calibration ensures consistent accuracy and should be performed according to your laboratorys schedule or after relocation or servicing. Each machine is supplied with a calibration certificate that confirms compliance with IS2281, ASTM E10, and BS 240 standards.Q: Where can this Brinell hardness tester be used?

A: Designed for versatility, the equipment is suitable for laboratory and industrial environments, including metal manufacturers, quality control labs, and research facilities. Its robust construction and adaptability make it effective for use in diverse conditions across India and beyond.Q: What benefits does the overload protection feature provide?

A: Overload protection safeguards both the machine and the test specimen from accidental overloading, thereby ensuring operator safety and maintaining the equipments accuracy and longevity. It also minimizes the risk of damage during setup or testing.Q: How is data output managed with this tester?

A: The machine provides manual readings of indentation measurements but is also equipped with provisions for digital documentation, making it easy to record and archive results for future reference or reporting needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Equipments Category

COMPUTERISED UNIVERSAL TESTING MACHINE

Price Range 10000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Humidity : 85% RH

Resolution : 0.01 N

Number of Specimens : 1 (at a time)

Test Speed : 0.01 500 mm/min (variable)

Mechanical Brinell Hardness Tester

Price Range 10000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Humidity : 85%

Resolution : 0.1 HB

Number of Specimens : Single

Test Speed : Standard manual operation

DIGITAL CHARPY / IZOD IMPACT TESTING MACHINE

Price Range 10000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Humidity : up to 85% RH

Resolution : 0.01 Joule

Number of Specimens : 1 per test

Test Speed : 5.2 m/s

ERICHSEN CUPPING TESTING MACHINE

Price Range 10000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Humidity : Up to 85% RH

Resolution : 0.01 mm

Number of Specimens : Single specimen at a time

Test Speed : 0.1 10 mm/min (adjustable)

Factory Address :

Plot No 47, Emerald Indl Estate, Kidc Indl Area, Deku Village, Khalapur Taluk,

Khopoli Raigad, Maharahtra

Send Inquiry

Send Inquiry