DIAMOND INDENTOR

DIAMOND INDENTOR Specification

- Operating Voltage

- Not Required

- Test Range

- For use in Hardness Testers

- Hardness

- Indenter Tip: 6000 HV Min.

- Equipment Type

- Diamond Indentor

- Humidity

- Up to 75% RH

- Mounting Type

- Direct fixture mounting

- Measuring Range

- Standard hardness test ranges

- Temperature

- 5C to 45C

- Features

- Durable, precise, long service life

- Automation Grade

- Manual

- Resolution

- High, depending on hardness tester

- Power Supply

- Not Required

- Interface Type

- Manual fit

- Number of Specimens

- Single point measurement

- Accuracy

- High precision indents, typically 1 m

- Response Time

- Immediate

- Application

- Hardness testing on metals and alloys

- Specimen Size

- Adaptable to various specimen sizes

- Capacity

- One indentor per test

- Machine Weight

- Approx. 250g

- Test Speed

- Manual operation

- Control Mode

- Manual

DIAMOND INDENTOR Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 04 Units Per Month

- Delivery Time

- 3-8 Week

About DIAMOND INDENTOR

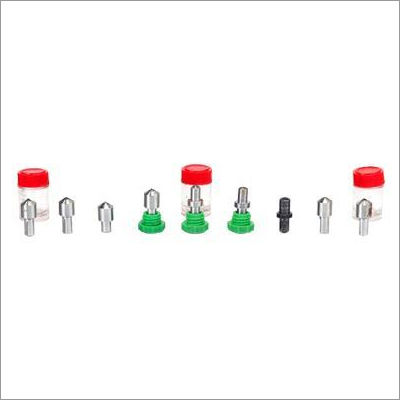

Diamond Indenters

Our company is a reckoned entity offering an exclusive assortment of Diamond Indenters. We develop these indenters using excellent quality materials and technology at our state of art machining facility. Our Diamond Indenters are primarily used in special matrix to test hardness of metals. Corrosion resistance, robust construction and durability are the main attributes of our indenters.

Further Details:

For C Scale Standard

For C Scale Special

For Superficial Scale

For Vickers Hardness Tester

High-Precision Diamond Indentor for Hardness Testing

Engineered for accuracy, the diamond indentor is specifically designed for use in Vickers, Rockwell, and Brinell hardness testers. Its resilient diamond tip, available in pyramidal or conical shapes, ensures reliable measurements with minimal deviation. The product offers excellent adaptability to various specimen sizes and excels under a wide range of laboratory conditions. Its alloy steel body and mirror-polished surface provide both durability and superior performance, making it an essential tool for accurate hardness evaluation of metals and alloys.

Versatile Compatibility and Ease of Use

This diamond indentor is compatible with several leading hardness testing systems, enabling users to seamlessly switch between testing protocols. No external power supply is necessary, and its manual control mode offers users full command over the testing process, ensuring immediate response and high measurement repeatability. The protective packaging ensures safe transportation and storage, maintaining tip integrity and long operational life.

FAQs of DIAMOND INDENTOR:

Q: How is the diamond indentor used in hardness testing?

A: The diamond indentor is mounted directly onto a compatible hardness tester such as Vickers, Rockwell, or Brinell. Under manual operation, it is pressed into the specimen, producing a precise indentation which is then measured to determine the materials hardness.Q: What types of hardness testers can this indentor be used with?

A: This diamond indentor is suitable for Vickers, Rockwell, and Brinell hardness testers. Its design ensures accurate performance across various machines, accommodating the requirements of multiple testing standards.Q: When should I use a pyramidal or conical diamond indentor tip?

A: Use the pyramidal tip (136) for Vickers or Berkovich hardness testing, which is ideal for a wide range of metals. The conical tip (120) should be used for Rockwell hardness tests, optimizing accuracy on those devices.Q: Where is the best environment to operate the diamond indentor?

A: The optimal operating conditions are within laboratories or industrial settings with controlled environments, where temperature is maintained between 5C to 45C and humidity does not exceed 75% RH, ensuring measurement stability.Q: What precautions should I follow during the testing process?

A: Ensure the indentor and specimen are clean and securely mounted. Operate the tester manually for steady control and store the indentor in its protective box after use to prevent tip damage and maintain precision.Q: What are the benefits of using this diamond indentor for hardness testing?

A: The primary benefits are high precision (1 m), long service life due to durable diamond tip and alloy steel body, compatibility with multiple testers, and reliable performance under various environmental conditions.Q: How adaptable is the indentor to different specimen sizes?

A: The diamond indentor accommodates various specimen sizes, enabling flexible testing across a broad spectrum of metallic materials by providing single-point measurement during each test.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Testing Equipments Category

COMPUTERISED UNIVERSAL TESTING MACHINE

Price Range 10000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Control Mode : Computer Controlled / Manual

Accuracy : Class 1 / 1%

Response Time : Instantaneous

Specimen Size : 10 50 mm diameter

COMPUTERISED BRINELL MICROSCOPE MODEL

Price Range 10000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Control Mode : PC Controlled

Accuracy : 0.01 mm

Response Time : Instantaneous with image capture

Specimen Size : Up to 200 mm height & 200 mm width

DIGITAL CHARPY / IZOD IMPACT TESTING MACHINE

Price Range 10000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Control Mode : Digital/Automatic

Accuracy : 1% of indicated energy

Response Time : Instantaneous

Specimen Size : 10 x 10 x 55mm (Charpy), 10 x 10 x 75mm (Izod)

ERICHSEN CUPPING TESTING MACHINE

Price Range 10000.00 - 600000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Control Mode : Manual and Motorized

Accuracy : 0.05 mm

Response Time : Instantaneous mechanical response

Specimen Size : Max. 100 x 100 mm

Factory Address :

Plot No 47, Emerald Indl Estate, Kidc Indl Area, Deku Village, Khalapur Taluk,

Khopoli Raigad, Maharahtra

Send Inquiry

Send Inquiry