Aggregate Impact Apparatus

Aggregate Impact Apparatus Specification

- Machine Type

- Manual

- Technology

- Mechanical

- Surface Treatment

- Powder Coated

- Accessories Type

- Measuring cylinder, Tamping rod, Metal base with vertical guides

- Control System

- Hand operated

- Operating Pressure

- Ambient

- Features

- Corrosion resistant, Rigid construction, Easy to operate

- Power Source

- Manual

- Accuracy

- 1%

- Automation Grade

- Manual

- Type

- Aggregate Testing Apparatus

- Material

- Mild Steel

- Function

- To determine the aggregate impact value

- Application

- Civil engineering laboratories, Construction material testing

- Voltage

- Not required (manual)

Aggregate Impact Apparatus Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 04 Per Month

- Delivery Time

- 3-8 Week

About Aggregate Impact Apparatus

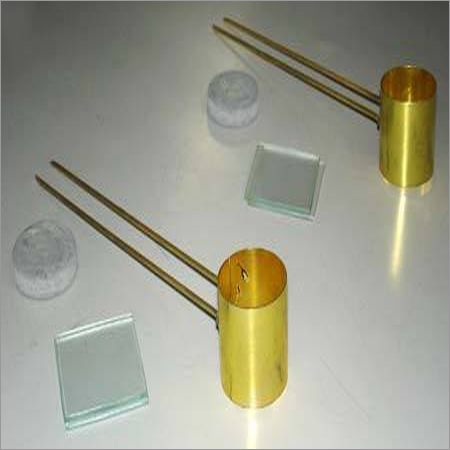

We are one of the leading manufacturers of Aggregate Impact Testing Apparatus developed as per IS: 2386 (Part IV) fabricated. The units we manufacture are of the best quality and have been manufactured keeping in mind the different customer specifications.Major Components :

- A base and support columns to form a rigid frame work

- The quick release triggers mechanism to ensure an effective free fall of hammer during test.

- A cylindrical cup

- A metal measure 75 mm inner dia x 50 mm deep

- A tamping rod

- A blow counter.

Rugged Precision for Aggregate Testing

Engineered for durability and exact measurement, the Aggregate Impact Apparatus provides a manual, ambient pressure solution to evaluate material resistance. With a precision hammer of 13.5 kg, adjustable drop height, and a carefully calibrated cylinder, users can rely on accurate aggregate impact values essential for quality-assured construction.

Designed for Ease and Efficiency

From its powder-coated finish to its smooth, safe edges, every component of this apparatus is crafted for straightforward operation. The included measuring cylinder, tamping rod, and metal base with vertical guides simplify setup and testing, while the packaging options ensure safe delivery across locations.

FAQs of Aggregate Impact Apparatus:

Q: How is the Aggregate Impact Apparatus used in civil engineering laboratories?

A: The apparatus is employed to assess the impact resistance of aggregates by means of a manual hammer drop onto a sample within a cylindrical container. Results help determine the suitability of aggregates in construction applications.Q: What are the key benefits of using this specific testing apparatus?

A: This device offers robust, corrosion-resistant construction, accurate results within 1%, and easy manual operation, ensuring reliable testing for aggregate impact value in construction material analysis.Q: When should aggregates be tested using this apparatus?

A: Aggregates should be tested before their use in construction projects or whenever there is a need to verify the materials suitability according to civil engineering standards.Q: Where is this impact testing machine typically installed or used?

A: It is predominantly used in civil engineering laboratories, educational institutions, and facilities involved in construction material quality control throughout India.Q: What accessories are provided with the Aggregate Impact Apparatus?

A: The apparatus is supplied with a measuring cylinder, tamping rod, and a metal base equipped with vertical guides for precise operation and accurate results.Q: How does the surface treatment enhance the apparatuss longevity?

A: Powder coating provides excellent corrosion resistance and contributes to the apparatuss rigidity and durability, making it suitable for repeated use in varied testing environments.Q: What is the process for determining aggregate impact value with this machine?

A: The procedure involves placing a pre-weighed aggregate sample in the cylinder, applying tamping, and conducting repeated drops of the hammer. The resulting data quantifies the aggregates impact resistance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Engineering Instruments Category

Ductility Testing Machine

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Accessories Type : Standard Briquette Moulds, Water Bath, Pulling Device

Surface Treatment : Powder Coated / Painted

Application : Construction, Asphalt Testing Laboratories, Road Engineering

Accuracy : 1 mm

Bitumen Extractor

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Accessories Type : Centrifuge Basket, Filter Paper, Jug

Surface Treatment : Powder Coated

Application : Laboratory, Road Construction, Asphalt Testing

Accuracy : High

Universal Permeability Apparatus

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Accessories Type : Standpipe, Overflow Pipe, Connecting Tubes, Glass Measuring Cylinder

Surface Treatment : Powder Coated

Application : Geotechnical Engineering, Soil Testing Laboratories

Accuracy : High Precision (1%)

Le Chatelier Mould

Price Range 10000.00 - 600000.00 INR / Number

Minimum Order Quantity : 1 Number

Accessories Type : Glass Plate, Weight

Surface Treatment : Polished Finish

Application : Cement Testing

Accuracy : High

Factory Address :

Plot No 47, Emerald Indl Estate, Kidc Indl Area, Deku Village, Khalapur Taluk,

Khopoli Raigad, Maharahtra

Send Inquiry

Send Inquiry